Predictive Maintainence

Machine breakdown affects the productivity of operations especially when the downtime is significant. This can be costly and affects the profitability of a business. Modern AI systems allow us to predict when an asset or machine is likely to fail so that necessary measures can be taken.

The Challenge

Previously preventive maintenance strategies were used. Preventive maintenance refers to a type of maintenance that you regularly perform on a machine to reduce the chance of it breaking down. Preventive maintenance aims at producing outcome-focused results for operating and maintaining based on the analysis. There are two ways for performing preventive maintenance, time-based and usage-based preventive maintenance.

On the other hand, reactive maintenance also known as Run to Failure is a simple method to execute. Under this strategy, you allow the machine to operate till it breaks down and then you perform the maintenance. However, you need to have a plan beforehand for the maintenance to reduce production risks and reduce unnecessary maintenance costs.

Early detection of the problem is the easiest way to avoid such issues. One of the ways to do that is through predictive maintenance. Predictive maintenance refers to a method of using machine learning to decide the optimal time of service for the machine. This assists in the maintenance of the machine and reducing the machine downtime by servicing the machine just before it breaks down.

The Process

Predictive maintenance relies on three main elements for its success.

Availability of data : The availability of data involves collecting historical data on the performance of your machine. Historical data consists of collecting data over the degradation process of the machine. For you to achieve this, you have to involve experts such as domain experts and data scientists. They are the ones responsible for collecting consistent data suitable for building the relevant machine learning models.

Framing of the problem : There are several questions that you have to ask when framing the issue. These questions include

- What type of output do you want the model to produce?

- Is there an appropriate historical data?

- Do you have all the records of the events?

- What is the time frame of your model to indicate a failure?

- What are your performance targets for the optimization of your model?

The answers to these questions are crucial in deciding which model and optimization strategy will suit which business. Under predictive maintenance, different modelling strategies exist which we will be discussed in the next section.

Once our prediction models are trained for different strategies then we evaluate these on test datasets. Prediction evaluation involves analyzing the outcome of the problem framing and coming up with the appropriate measures. Such measures include analyzing the cost for maintenance and potential savings that can be generated from early prediction and diagnosis of assets.

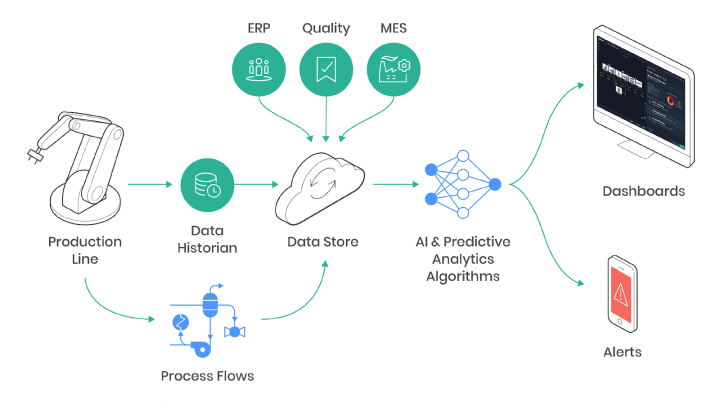

After this we deploy our Machine Learning system and connect it to our Analytics Dashboard. Our system is integrated with DB historian to get data and perform predictions in realtime.

The Technical Bit

We train a range of different models which serve different purposes. Below are some of the strategies used for training and testing of different kind of models that together make up our machine learning system for Predictive Maintenance.

- Flagging of unusual behaviour : Under this strategy we train anomaly detection models which detect abnormalities in assets and sensor networks

- Regression model strategy for predicting the Remaining Useful Lifetime (RUL). Here, we need to ensure that you have all the data, label each vent and have several events of each type of failure. These models at any point in time predict the remaining useful life of an asset.

- Survival model strategy to predict the failure probability over a given period. This strategy is best if you want to find the degradation process of the machine and its failure probability. This strategy requires static data and failure time information of each machine

- Classification model strategy that is useful in predicting the failure of a tool during a given time frame. Here, the description of failure is on a time frame and it deals with multiple types of failures.

The Results

Training and deploying predictive maintenance solution yields phenomenal results for business in terms of cost savings and increasing production output.

The use of traditional maintenance implies that you have to wait for a problem to occur before fixing it. This means that during the maintenance period, the machine won’t be operating which leads to loss of revenue during that period. On the other hand, predictive maintenance identifies when the machine will have to undergo maintenance. This gives operators time to make alternate arrangements for maintenance.

With preventive maintenance solutions, businesses have to schedule maintenance even when it is not needed. This results in unnecessary costs and wastage of resources.

Interested in finding out how Intelligent Predictive Maintenance solutions can help your business save money?

Schedule a call with one of our team members today to find out how.